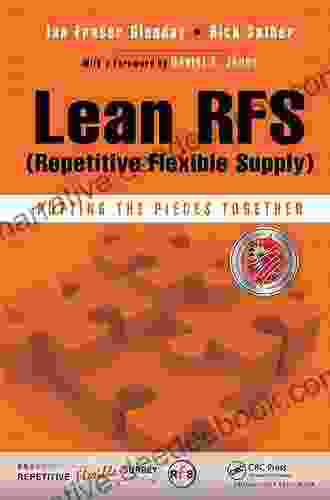

Lean RFS: A Comprehensive Guide to Repetitive Flexible Supply in Manufacturing

The manufacturing industry faces constant pressure to reduce costs, improve quality, and increase flexibility in response to changing market demands. Lean manufacturing practices have emerged as a powerful tool to address these challenges. One specific approach within Lean manufacturing is Lean RFS (Repetitive Flexible Supply),which focuses on optimizing repetitive production processes.

4.5 out of 5

| Language | : | English |

| File size | : | 10489 KB |

| Print length | : | 168 pages |

| Screen Reader | : | Supported |

| X-Ray for textbooks | : | Enabled |

Lean RFS aims to eliminate waste and inefficiencies while increasing the flexibility and agility of manufacturing systems. By applying Lean principles to repetitive supply chains, manufacturers can achieve significant improvements in:

- Production efficiency

- Inventory levels

- Lead times

- Product quality

- Responsiveness to market fluctuations

Principles of Lean RFS

The principles of Lean RFS are based on the Toyota Production System and the concept of value stream mapping. Lean RFS emphasizes the following principles:

- Identify and Eliminate Waste: Waste is any activity that does not add value to the product or service, such as overproduction, waiting, transportation, and defects. Lean RFS aims to eliminate waste at every step of the production process.

- Create Flow: Lean RFS strives to create a continuous flow of materials and information throughout the production process. This involves minimizing batch sizes, reducing setup times, and eliminating bottlenecks.

- Pull Production: Instead of pushing products through the production process based on forecasts, Lean RFS uses a pull system where products are only produced when there is actual demand. This helps reduce inventory levels and improve responsiveness.

- Empower Employees: Lean RFS recognizes the importance of employee involvement in continuous improvement. Employees are encouraged to identify and address waste, suggest improvements, and take ownership of their work processes.

Implementation of Lean RFS

Implementing Lean RFS involves a structured approach that typically includes the following steps:

- Value Stream Mapping: The first step is to map the current production process to identify areas of waste and inefficiency. This involves creating a visual representation of the flow of materials, information, and time throughout the process.

- Waste Identification: Using the value stream map, the team identifies and classifies waste into seven categories: overproduction, waiting, transportation, overprocessing, inventory, defects, and underutilized employee potential.

- Root Cause Analysis: For each type of waste identified, the team investigates the underlying causes and develops countermeasures to address them.

- Process Redesign: The team redesign the production process to eliminate waste and create flow. This may involve changes to layout, equipment, work instructions, and supply chain management practices.

- Continuous Improvement: Lean RFS is an ongoing process of continuous improvement. The team regularly monitors performance, identifies new opportunities for improvement, and implements changes to enhance the system.

Benefits of Lean RFS

Implementation of Lean RFS can bring numerous benefits to manufacturing organizations, including:

- Reduced Production Costs: Elimination of waste leads to significant cost savings in areas such as inventory, labor, and machine downtime.

- Improved Quality: Continuous improvement and waste elimination result in higher quality products.

- Shorter Lead Times: Faster production flows and reduced setup times reduce lead times, improving responsiveness to customer demand.

- Reduced Inventory Levels: Pull production minimizes inventory levels, freeing up capital and reducing holding costs.

- Increased Flexibility: Lean RFS improves the ability of manufacturers to adapt to changing market demands, such as product variations or fluctuations in demand.

- Improved Employee Morale: Employee involvement and empowerment lead to higher job satisfaction and increased productivity.

Lean RFS is a powerful manufacturing strategy that can help organizations achieve significant improvements in efficiency, flexibility, and profitability. By applying Lean principles to repetitive production processes, manufacturers can eliminate waste, create flow, and empower employees to drive continuous improvement. As a result, they can gain a competitive advantage in today's dynamic and demanding manufacturing environment.

4.5 out of 5

| Language | : | English |

| File size | : | 10489 KB |

| Print length | : | 168 pages |

| Screen Reader | : | Supported |

| X-Ray for textbooks | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Reader

Reader Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Preface

Preface Synopsis

Synopsis Footnote

Footnote Codex

Codex Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Reference

Reference Encyclopedia

Encyclopedia Thesaurus

Thesaurus Character

Character Resolution

Resolution Librarian

Librarian Catalog

Catalog Stacks

Stacks Study

Study Research

Research Reading Room

Reading Room Rare Books

Rare Books Literacy

Literacy Storytelling

Storytelling Awards

Awards Reading List

Reading List Theory

Theory Textbooks

Textbooks Gary Mottram

Gary Mottram Dana Landers

Dana Landers Anjali Sebastian

Anjali Sebastian Sylviane Granger

Sylviane Granger Giuseppina Pellegrino

Giuseppina Pellegrino Yannick Haenel

Yannick Haenel Max Ehrlich

Max Ehrlich Fred Campano

Fred Campano Sarah Burns

Sarah Burns J Zachary Pike

J Zachary Pike Lay Hwee Yeo

Lay Hwee Yeo Naushad Sheikh

Naushad Sheikh Crystal Schwanke

Crystal Schwanke Eric Macintosh

Eric Macintosh Elizabeth Hoyt

Elizabeth Hoyt Max Scratchmann

Max Scratchmann Yonas Gorfe

Yonas Gorfe William Stewart

William Stewart William Damon

William Damon Ford Harding

Ford Harding

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Winston HayesFocused and Fearless: My Everyday Journal for Unlocking Your Potential and...

Winston HayesFocused and Fearless: My Everyday Journal for Unlocking Your Potential and...

Richard WrightEdward Said's Legacy of Emancipation and Representation: A Journey Through...

Richard WrightEdward Said's Legacy of Emancipation and Representation: A Journey Through... Brennan BlairFollow ·16.6k

Brennan BlairFollow ·16.6k Enrique BlairFollow ·15.6k

Enrique BlairFollow ·15.6k Floyd PowellFollow ·16.2k

Floyd PowellFollow ·16.2k Roald DahlFollow ·14.9k

Roald DahlFollow ·14.9k Elliott CarterFollow ·2.6k

Elliott CarterFollow ·2.6k Cameron ReedFollow ·9.6k

Cameron ReedFollow ·9.6k Dennis HayesFollow ·4.4k

Dennis HayesFollow ·4.4k Deacon BellFollow ·10.9k

Deacon BellFollow ·10.9k

Dallas Turner

Dallas TurnerParasols and Peril: Adventures in Grace

In the quaint town...

Caleb Carter

Caleb CarterFlight Attendant Joe: A Dedicated Professional in the...

Flight Attendant Joe...

Jerry Ward

Jerry WardPick Lottery The List For 23 States August 15 2024

The Pick Lottery is a multi-state lottery...

Hudson Hayes

Hudson HayesHow the Media Wields Dangerous Words to Divide a Nation

In a world where the media is...

Curtis Stewart

Curtis StewartThe Magic Mala: A Story That Changes Lives

In the realm of ancient traditions and...

Raymond Parker

Raymond ParkerEarthly Meditations: A Poetic Tapestry of Nature,...

In the realm of contemporary...

4.5 out of 5

| Language | : | English |

| File size | : | 10489 KB |

| Print length | : | 168 pages |

| Screen Reader | : | Supported |

| X-Ray for textbooks | : | Enabled |